From machine data to insight

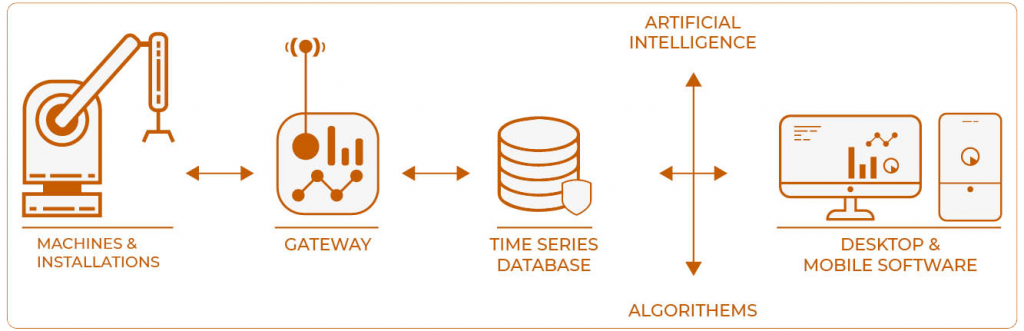

With Eniris, we developed a data analysis platform Eniris Insights for machine builders, integrators and their customers.

This platform is fully adapted to industry 4.0 and gives you insight into your installation's data (uptime, downtime, energy consumption, condition parameters, etc.). We also provide remote updating of your software, remote parameter adjustment and predictive maintenance.

Moreover, Eniris Insights is technology independent: controllers, sensors, PLCs, HMIs, ... can easily be connected to this platform.

Besides visualisation and storage of measurement data, technical analyses are also possible with this platform.

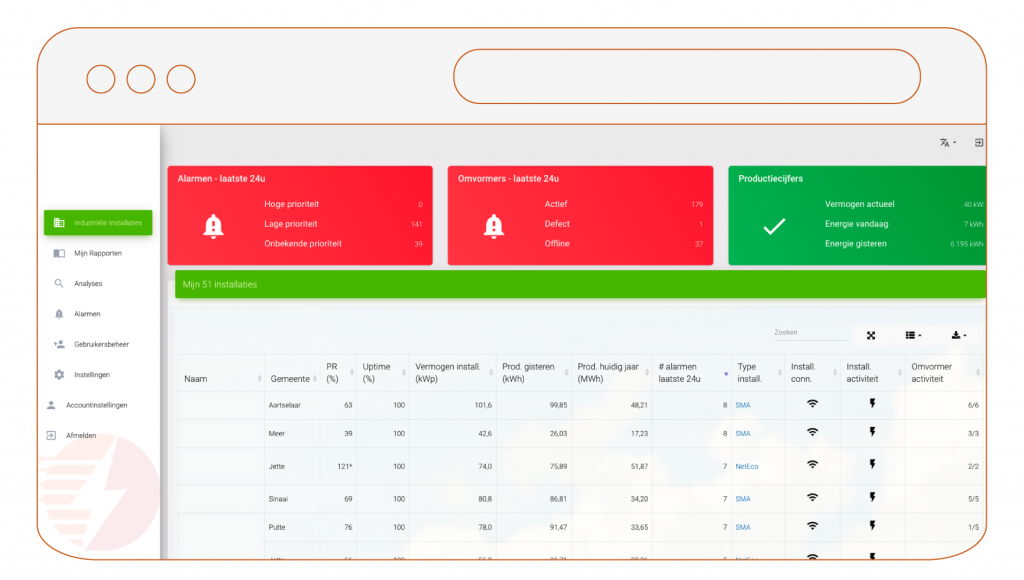

At a glance

Insight into the key performance indicators of all your installations.

All Key Performance Indicators (KPIs) at a glance

- OEE

- Complete productive time

- Planned production time

- Ideal cycle time

- Duration

- Total count

- Correct number

- Good parts

- Quality

- Prestations

- Availability

Predictive maintenance

By automatically identifying patterns in the data, Eniris Insights can predict when problems will occur. This allows you to plan maintenance or replacement of parts.

Save on your maintenance costs

- Anomaly detection (with machine learning)

- Prediction of failure

User management

Controlling access has never been easier.

Different clearance levels

With Eniris Insights you can easily add and maintain technicians or administrators in a user-friendly way. For each type of user, there are different access levels where data can be accessed.

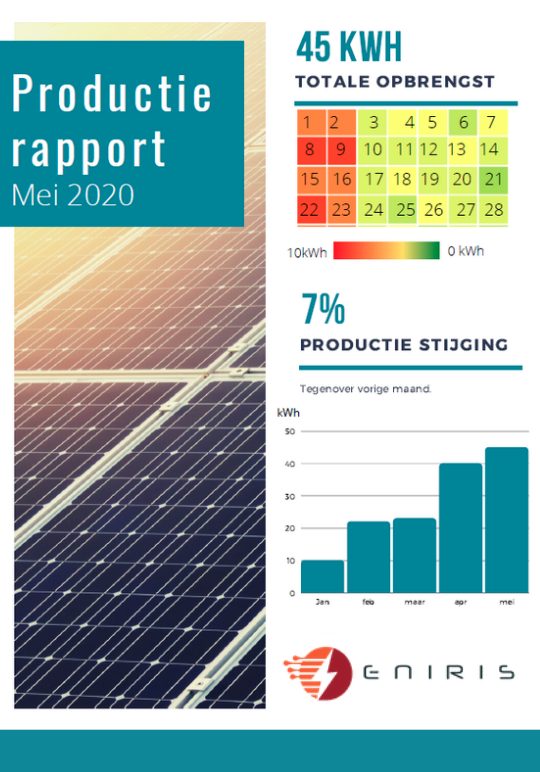

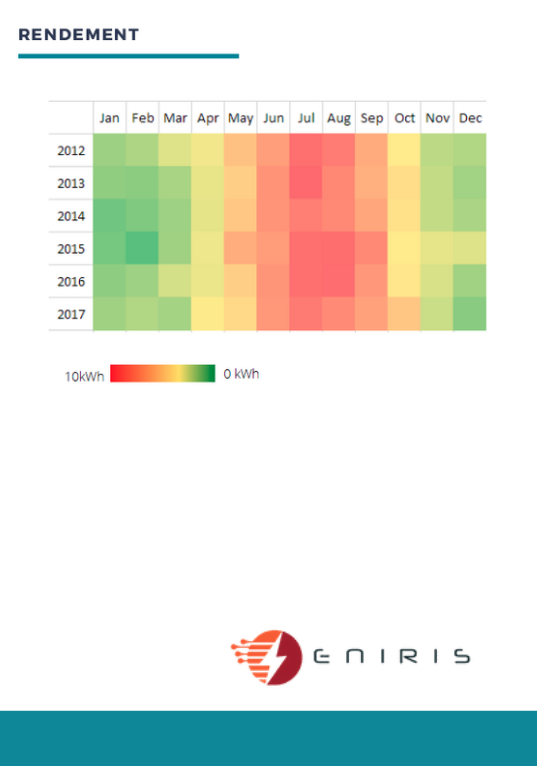

Reports

Adapted for each type of user.

We develop customised templates in which we process production or financial figures per factory, line or team.

Alarm management & ticketing

Set your own alarm levels, independent of underlying portals/PLCs.

Increased efficiency of your alarm processing

- Overarching registration and processing

- Assigning different priorities

- Forward alarms by mail, popup or SMS (optional)

- Integration with your ERP system / digital work orders.

- Ticketing within

Eniris Insights

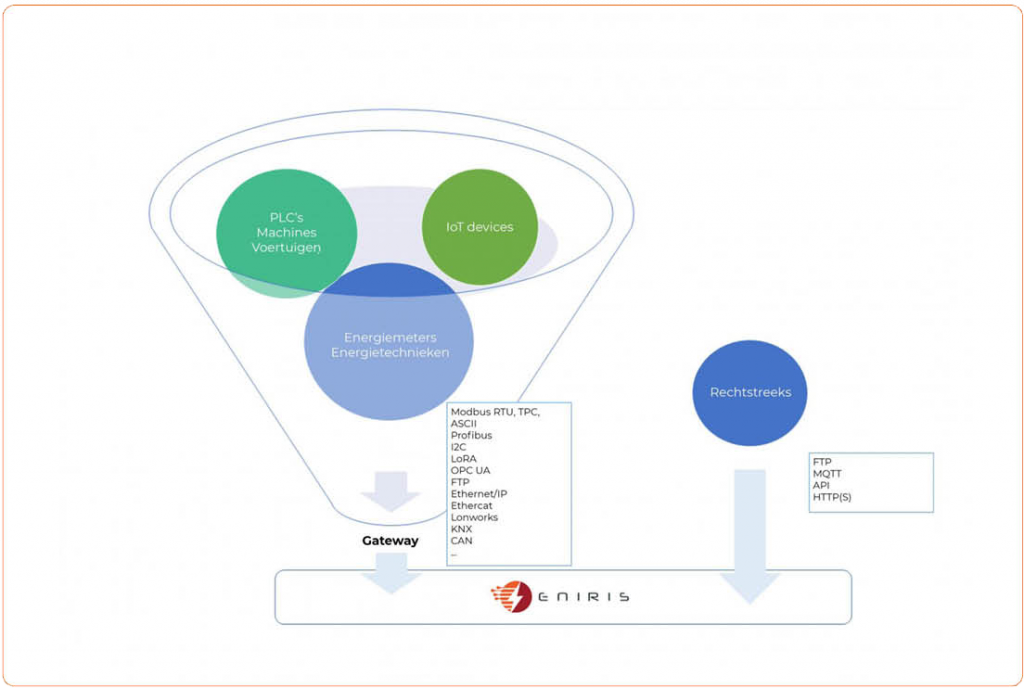

Broad support

In every environment, there are different machines of different brands and ages.

No problem for Eniris!

Eniris Insights handles a wide range of protocols and interfaces.

Brand Independent

- OPC UA

- CAN

- MQTT

- Modbus RTU/TCP

- FTP(S),

- (e.g. for your SCADA)

Do not hesitate to contact us regarding the accessibility of your installation(s).

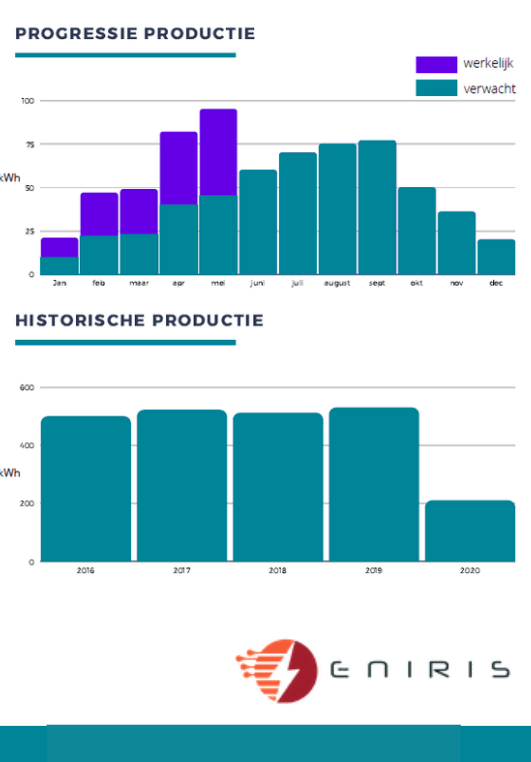

Indispensable analyses

Whether it is a quick visual check or a detailed comparison,

Eniris Insights provides you with the helpful tools.

From data analysis to decision

- Discover the weak links in your production (which machines should be revised or replaced).

- Reduce the number of unplanned maintenance stops.

- Increase the turnaround time.

- Reduce energy costs.

Infographics

Real-time KPIs and OEE parameters are displayed on the large screens in the production hall. You can immediately see how a particular production line is performing and adjust accordingly.

For large displays

The system includes an HDMI interface so that any wide-screen TV can be connected directly.

Contact us

Bart Verheecke

bart@eniris.nl

+31 (0) 613 42 82 15